Industry 4.0 is commonly referred to as the Fourth Industrial Revolution or Smart Factory. This concept is a combination of Multiple Technologies such as Cyber-Physical Systems (the Mechanism that is controlled or monitored by Computer-Based Algorithms, Tightly Integrated with the Internet and its users), the Internet of Things, Cloud Computing, and Cognitive Computing.

AARK Technology Hub understands the client's Business case, Conduct Successful Pilots, help client organization to understand where action is needed, and Organize client processes to maximize new outcomes.

Advanced Digital Technology is already used in manufacturing, but with Industry 4.0, it will Transform Production. Recent advances in Industry 4.0 Technologies are making possible a more efficient approach to assembly. To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries in these various regions. This Technological Infrastructure is still in its early stages of Development.

Get In Touch

Our Industry 4.0 Development Process

The development process may vary depending on the specific needs and complexities of the business. It's important to customize the process to align with the business unique goals and requirements.

Identify Goals and Objectives

Defining the goals and objectives of business Industry 4.0 initiative. Determine the specific areas of improvement business want to target, such as operational efficiency, productivity, quality, or customer satisfaction.

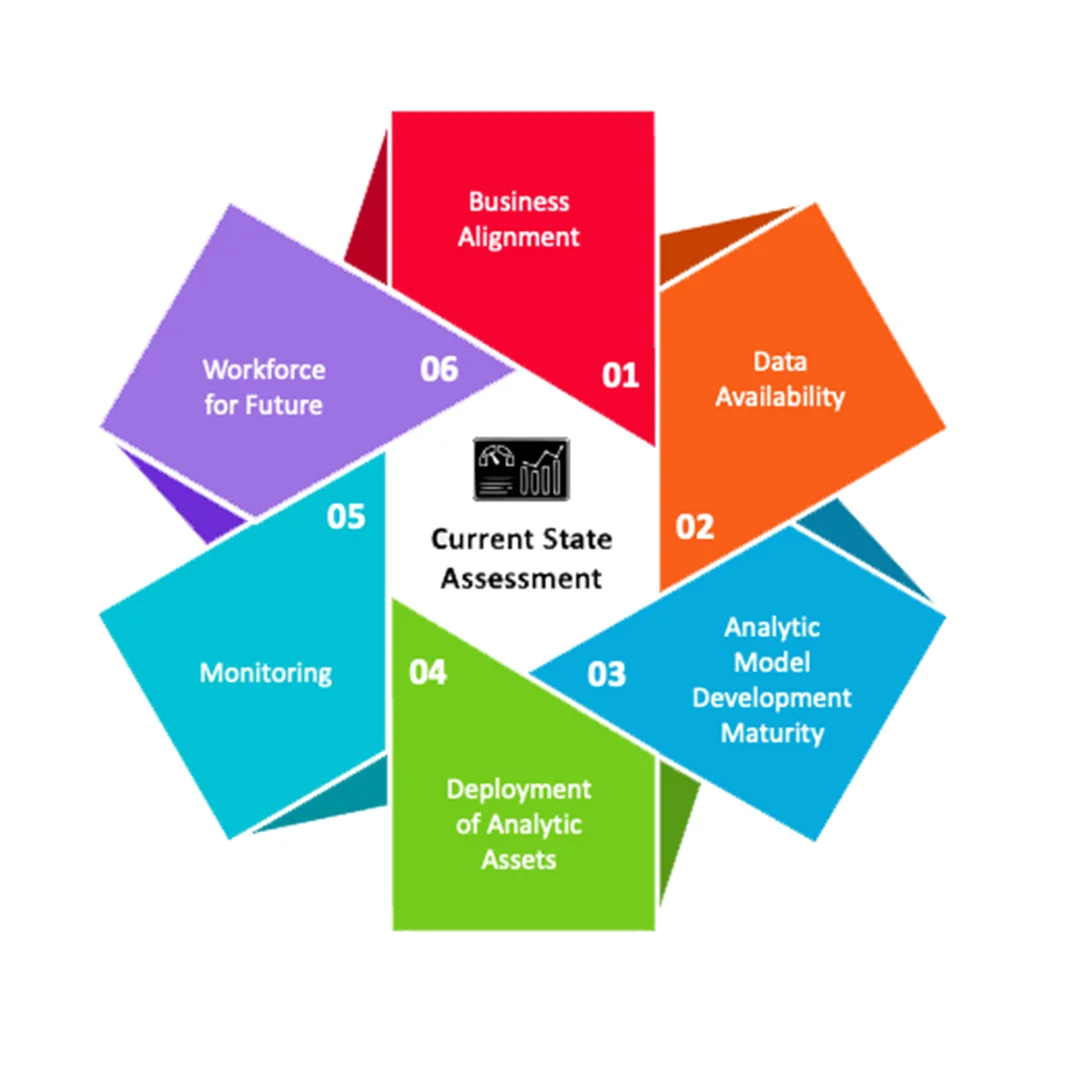

Assess Current State

Evaluate existing infrastructure, processes, and technologies to identify gaps and areas for improvement. This assessment helps in understanding the current capabilities, identifying potential bottlenecks, and determining the readiness for Industry 4.0 implementation.

Develop a Roadmap

Create a roadmap that outlines the steps required to achieve Industry 4.0 goals. Define milestones, timelines, and key performance indicators (KPIs) to track progress. Consider factors like budget, resources, and implementation priorities while developing the roadmap.

Technology Selection

Select the appropriate technologies that align with business objectives. This may include technologies like IoT devices, sensors, automation systems, data analytics tools, cloud platforms, and cybersecurity solutions.

Pilot Projects

Start with pilot projects to test the selected technologies and validate their effectiveness within specific operational environment. Choose a small-scale implementation to minimize risks and gather valuable insights for scaling up later.

Implementation and Integration

Once the pilot projects are successful, proceed with the wider implementation and integration of Industry 4.0. This involves deploying sensors, connecting devices, setting up data collection systems, integrating software applications, and establishing connectivity between different components.

Data Collection and Analysis

Collect data from sensors, machines, and processes. Use data analytics tools and techniques to derive meaningful insights, identify patterns, and make data-driven decisions. Analyze the data to improve operational efficiency, optimize maintenance schedules, and enhance overall performance.

Cybersecurity Measures

Implement robust cybersecurity measures such as securing network infrastructure, implementing access controls, conducting regular vulnerability assessments, and training employees to protect connected systems and data.

Training and Change Management

Provide training to employees on how to effectively utilize and interact with the new Industry 4.0 technologies. Promote a culture of continuous learning and adaptation to embrace the changes brought by Industry 4.0.

Continuous Improvement

Industry 4.0 is an ongoing process of continuous improvement. Monitor the performance of your implemented solutions, measure KPIs, and gather feedback. Identify areas for further optimization and implement iterative improvements to drive efficiency, productivity, and competitiveness.